Search This Supplers Products:Punch machinemanipulatorLeveling machineServo feederStraightening machineUncoiler

Special for thin plate type 3-in-1 servo decoiler straightener feeder machine

- group name

- Decoiler Straightener Feeder

- Min Order

- 1 piece

- brand name

- Chance Move Machinery Manufacturer

- model

- GLK2

- Nearest port for product export

- Shenzhen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union

- update time

- Fri, 26 Dec 2025 22:06:46 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

1.It is suitable for coil material with maximum material width of 800mm and maximum thickness of 3.2mm. This machine is integrated with uncoiling and leveling feeding three machines and working space will be minimized by innovative structure of the machine.

2.Human-computer interface is adopted to simplify operating and ease of feeding.

3.Imported servo system and ensures high precision feeding.

4.Feeding roller and leveling roller by special heat treatment, high hardness ( HRC62 °) .

5.Various options are available for different sizes of punching machines and operational requirements.Special standard is also accepted.

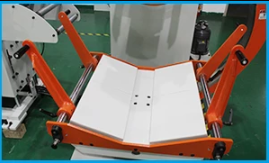

The material is safely and smoothly moved to the main shaft expansion and contraction structure of the uncoiler to support the material during uncoiling so as to facilitate the material belt to smoothly enter the leveler, and the trolley is equipped with a material roll dumping prevention mechanism for moving narrower material rolls.

Used to fix the material roll on the expanded and contracted position of the main shaft of the material rack, a support table supporting the inner diameter of the material roll, and to make the main shaft rotate intermittently to uncoil and discharge material through the material ring control instruction during automatic operation.

Compacting the material also prevents the material roll from loosening after the band is removed, and prevents the material roll from unraveling during automatic operation.

It is used to position the width of the material roll and is easy to operate.

The key mechanical parts and electronic components in the control system are all made of famous brands in Japan or Europe and America, so that the core technology of the products can be monitored.

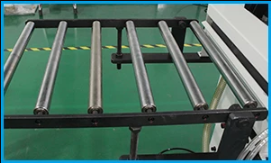

All correction wheels adopt GCR 15 GCr15 steel, which is used to correct the surface smoothness of the material and feed the material to the stamping equipment according to the set length and speed.

For manually adjusting the correction amount.

A hard chrome plating roller is installed on the material support frame to ensure the reliable transfer of the material belt to the mold after the fixed length.

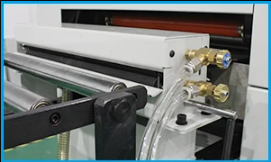

It is used for oiling the surface of the material, and the amount of oiling and oiling interval are electronically controlled and adjustable.

|

Model

|

GLK2-300

|

GLK2-400

|

GLK2-500

|

GLK2-600 | GLK2-800 | GLK2-1000 |

Width of Material(mm) | 50-300 | 50-400 | 50-500 | 50-600 | 50-800 | 100-1000 |

Thickness of Material(mm) | 0.3-3.2 | |||||

Max Coil Weight(kg) | 2000 | 2000 | 3000 | 5000 | 5000 | 7000 |

Coil I.D(mm) | 508 | |||||

Max Coil O.D.(mm) | 1200 | |||||

Max.line Speed(m/min) | 16 | |||||

Standard Feed Accuracy (mm) | ±0.2 | |||||

Working Rollers(pcs) | 6 on top / 5 on bottom | |||||

Standard Feed Height (mm) | 1200±100 | |||||

Power Voltage(v) | AC220V 50HZ/AC380V 50HZ | |||||

|

Operating Air (Mpa)

|

0.5-0.6

|

|||||

Mandrel Expansion | Hydraulic | |||||

Main Motor(kw) | AC2.9 | AC2.9 | AC4.4 | AC4.4 | AC5.5 | AC5.5 |

Rack motor (kw) | AC1.5 | AC1.5 | AC1.5 | AC2.2 | AC2.2 | AC3.7 |

Model | Feeding thickness(mm) | |||||||||

|

0.3

|

1.0 | 1.3 | 1.6 | 2.0 |

2.3

|

2.5 | 2.8 | 3.2 | ||

|

Feeding width (mm) |

GLK2-300

|

300

|

250 | |||||||

GLK2-400 | 400 | 250 | ||||||||

GLK2-500 | 500 | 250 | ||||||||

|

GLK2-600

|

600

|

230 |

||||||||

|

GLK2-700

|

700

|

200 |

||||||||

GLK2-800 | 800 | 180 | ||||||||