Search This Supplers Products:Punch machinemanipulatorLeveling machineServo feederStraightening machineUncoiler

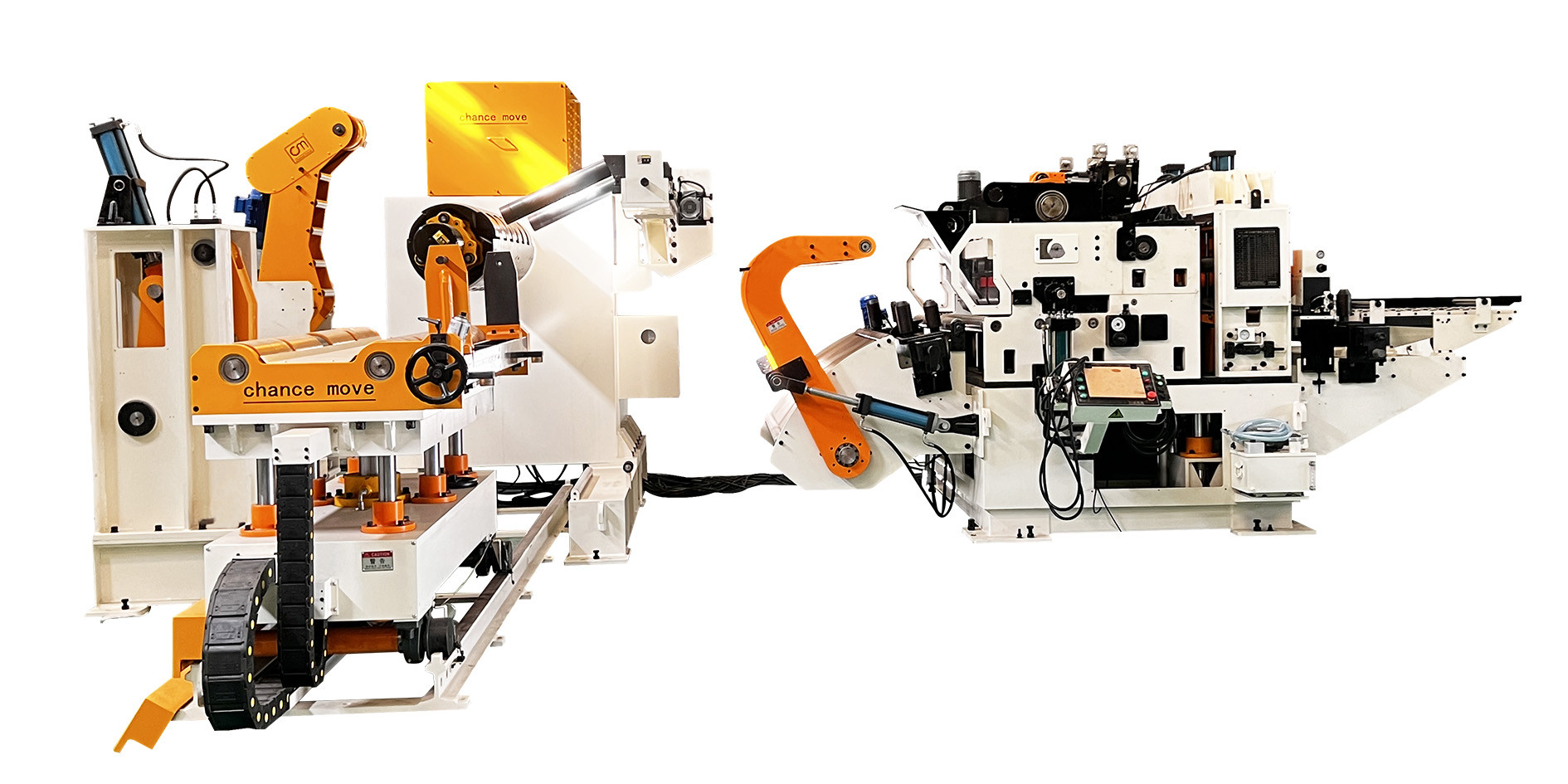

Special for meddle plate type 3-in-1 servo decoiler straightener feeder machine

- group name

- Decoiler Straightener Feeder

- Min Order

- 1 piece

- brand name

- Chance Move Machinery Manufacturer

- model

- GLK3

- Nearest port for product export

- Shenzhen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union

- update time

- Wed, 07 Jan 2026 21:06:14 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

adopts man-machine interface

Detailed

1.Working space will be minimized by innovative structure of the machine.

2.Human-computer interface is adopted to simplify operating and ease of feeding.

3.Imported servo system and ensures high precision feeding.

4.Feeding roller and leveling roller by special heat treatment, high hardness ( HRC62 °) .

5.Various options are available for different sizes of punching machines and operational requirements.Special standard is also accepted.

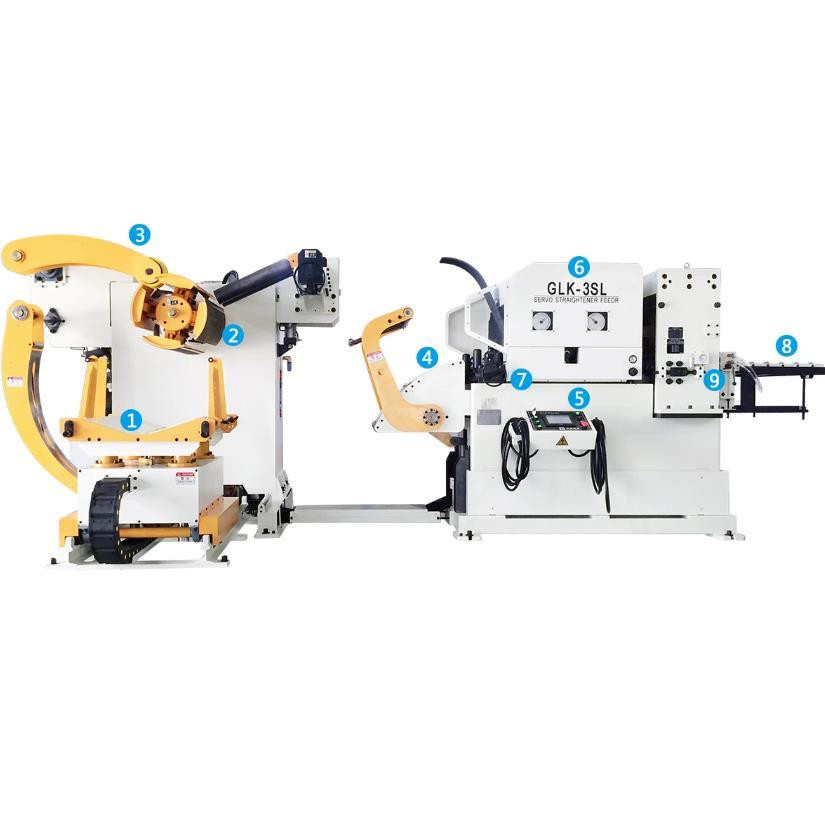

Material seat shape: the bearing surface is V - shaped structure, and the surface is painted and rustproof.

The expansion mode adopts hydraulic pull rod type, and the spindle drive double row large pitch chain drive.

Using cylinder drive.

Swing arm control is controlled by touch screen and driven by air cylinder, which is used to guide the material head to enter the leveling machine and make the material smoothly enter the leveling device.

The correction amount is adjusted by using eccentric worm, leveling the material and feeding the material according to the requirements.

Dial display, eccentric shaft end with dial for reference.

Install the telescopic handle on the end of the bracket, and pull it out manually.

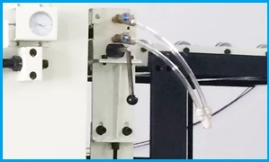

Used for oiling material surface.

|

Model

|

GLK3-400

|

GLK3-600

|

GLK3-800

|

GLK3-1000 |

|

Width of Material(mm)

|

50-400

|

50-600

|

50-800

|

100-1000 |

|

Max Coil Weight(kg)

|

5000

|

5000

|

7000

|

7000 |

Thickness of Material(mm)

| 0.5-4.5 | |||

|

Coil I.D(mm)

|

Φ508

|

|||

Max Coil O.D.(mm) | Φ1400 | |||

Max Feeding Length(mm) | ~500※ | |||

Max.line Speed(m/min) | 16-24 | |||

Working Rollers | 4 on top / 3 on bottom | |||

Feeding Rollers | 1 group | |||

Main Motor(kw) | AC4.4 | AC4.4 | AC5.5 | AC7.5 |

Uncoil Expansion | Hydraulic | |||

Rack motor (kw) | AC2.2 | AC2.2 | AC3.7 | AC3.7 |

Power Voltage(v) | AC220V 50HZ/AC380V 50HZ | |||

Operating Air (Mpa) | 0.5-0.6 | |||

|

Model

|

GLK3-400

|

GLK3-600

|

GLK3-800

|

GLK3-1000 | |

|

Thickness (mm) |

0.5-0.8 |

400

|

600

|

800

|

1000 |

1.0 | 400 | 600 | 800 | 750 | |

1.2 |

400

|

600

|

700

|

600 | |

1.6 | 400 | 590 | 480 | 430 | |

1.8 | 400 | 500 | 420 | 380 | |

2.0 | 400 | 430 | 370 | 330 | |

2.3 | 400 | 360 | 320 | 290 | |

2.8 |

370

|

290

|

250

|

230 | |

3.2 | 300 | 250 | 220 | 200 | |

4.5 | 160 | 160 | 150 | 110 | |