Search This Supplers Products:Punch machinemanipulatorLeveling machineServo feederStraightening machineUncoiler

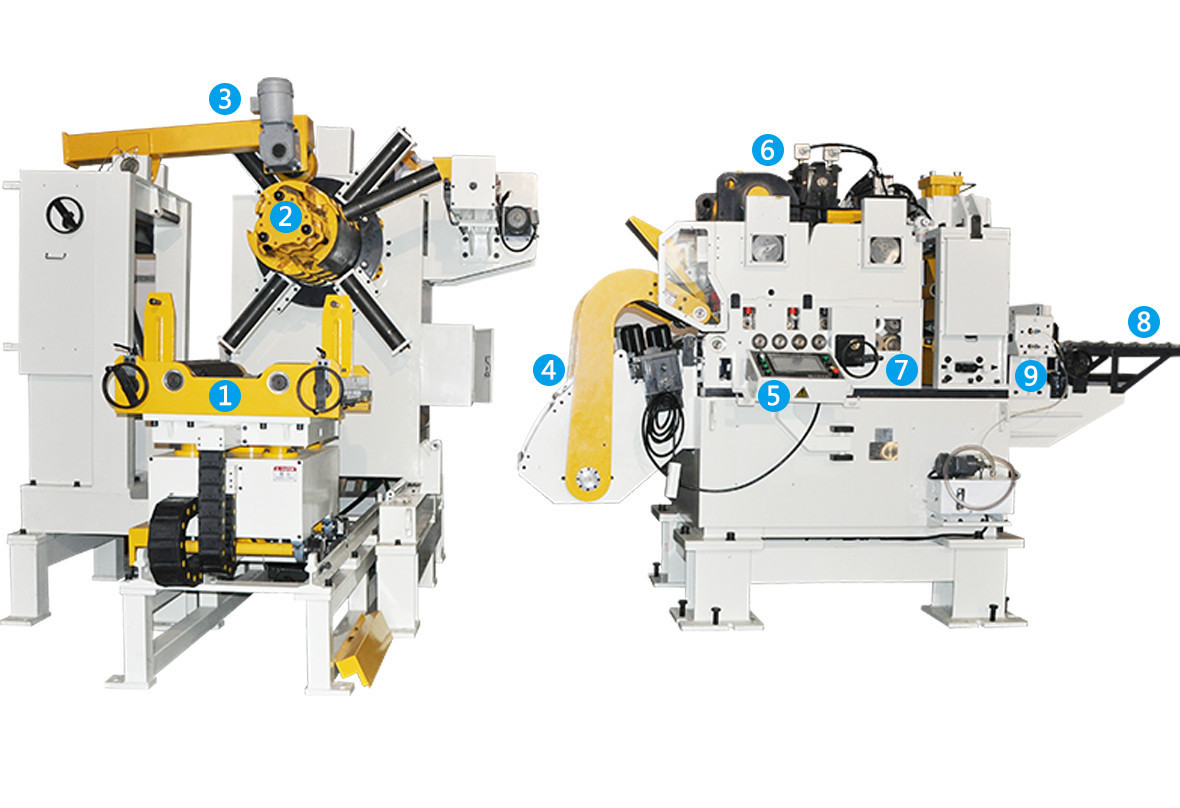

Thick plate type 3-in-1 servo decoiler straightener feeder machine

- group name

- Decoiler Straightener Feeder

- Min Order

- 1 piece

- brand name

- Chance Move Machinery Manufacturer

- model

- GLK5

- Nearest port for product export

- Shenzhen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union

- update time

- Thu, 01 Jan 2026 16:56:50 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

1.The use of nine working rollers and reinforced frame body structure, effectively overcome the high rigidity of the plate, improve the leveling accuracy of the material, so that the correction of high strength coil is possible.

2.High rigidity, high flatness.

3.Corresponding material width 600-1800mm and thickness 9.0mm.

4.The upside-down leveling roller set can be easily used for cleaning and maintenance of the roller.

5.The stepper deceleration motor can adjust the correction amount electrically, and the touch screen can input the correction amount directly, with the function of storing user parameters, which can be directly called out for use next time.

Option

1.Feeding Trolley

2.Optional Lubrication Unit

3.Hydraulic Plate Shearing Machine

4.Discharging Bracket

|

Model

|

GLK5-600

|

GLK5-800

|

GLK5-1000

|

GLK5-1300 |

Thickness of material(mm) | 0.8-9.0 | |||

|

Width of material(mm) |

70~600

|

70~800

|

100~1000

|

100~1300 |

Max Coil Weight(kg) | 5000 | 5000 | 7000 | 10000 |

|

Coil O.D.(mm) |

Φ1400

|

|||

Coil I.D.(mm) | Φ508 | |||

Feeding Length(mm) | ~500※ | |||

Feeding Speed(m/min) | 16 | |||

Working Rollers(pcs) | 5 on top / 4 on bottom | |||

Back up Roller | Provided | |||

Standard Feed Accuracy(mm) | ±0.2 | |||

Main Motor(kw) | AC15 | AC15 | AC22 | AC30 |

Rack motor (kw) | AC3.7 | AC3.7 | AC5.5 | AC7.5 |

Mandrel Expansion | Hydraulic | |||

Power Voltage(v) | AC220V 50HZ/AC380V 50HZ | |||

Operating Air (Mpa) | 0.5-0.6 | |||

Standard Feed level(mm) | 1200±100 | |||

|

Width

|

Material thickness(mm)

|

|||||||

|

Model

|

0.8-3.2

|

4.0 | 4.5 | 5.0 |

6.0

|

7.0

|

8.0 | 9.0 |

|

GLK5-600

|

600

|

450

|

331

|

253 | 200 | |||

|

GLK5-800

|

800

|

648 |

450

|

331

|

253 | 200 | ||

GLK5-1000 | 1000 | 800 | 648 | 450 | 331 | 253 | 200 | |

GLK5-1300 | 1300 | 1013 | 800 | 648 | 450 | 331 | 253 | 200 |

The above figures are the material having yield strength of σ s=245N/mm² max ( Tensile strength of σ b=392N/mm²)

|

Width

|

Material thickness(mm)

|

||||||||

|

Model

|

2.3

|

2.8 | 3.2 | 4.0 | 4.5 | 5.0 |

6.0

|

7.0

|

8.0 |

|

GLK5-600

|

533

|

432 | 374 | 292 | 257 | 228 |

180

|

132

|

101 |

|

GLK5-800

|

527

|

427 | 369 | 289 | 254 | 225 |

180

|

132

|

101 |

GLK5-1000 | 521 | 422 | 365 | 286 | 251 | 223 | 180 | 132 | 101 |

GLK5-1300 | 511 | 414 | 358 | 281 | 246 | 219 | 178 | 132 | 101 |

The above figures are the material having yield strength of σ s=613N/mm² max ( Tensile strength of σ b=980N/mm²)