Search This Supplers Products:Punch machinemanipulatorLeveling machineServo feederStraightening machineUncoiler

Uncoiling and leveling feeder special for high-strength plate

- group name

- Decoiler Straightener Feeder

- Min Order

- 1 piece

- brand name

- Chance Move Machinery Manufacturer

- model

- GLK4-H

- Nearest port for product export

- Shenzhen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW

- Acceptable payment methods

- T/T, L/C, PayPal, Westem Union

- update time

- Wed, 04 Feb 2026 17:13:02 GMT

Packging & Delivery

-

Min Order1 piece

Briefing

Adopt color LCD display.

Large-size touch screen.

Detailed

Product Description

Three - machine integrated uncoiling and leveling feeder special for uncoiling high-strength plate

Product Features

1.Working space will be minimized by innovative structure of the machine.

2.The operation panel adopts color liquid crystal display, large size touch screen, high clear operation picture, and operation safety system, so that even first-time users can operate at ease.

3.Sound operating system user-friendly design will shorten the preparatory work and advanced automatic diagnosis system, to help operators quickly control the outstanding performance of the machine.

4.Imported servo system and ensures high precision feeding.

5.Feeding roller and leveling roller by special heat treatment, high hardness ( HRC62 °) wear resistance, long service life.

6.Specially designed for the strong thick plate up and down leveling back up roller set, can achieve the guaranteed stress elimination effect.

7.The design concept of doubling the safety factor can prolong the safe service life of the equipment.

8.Various options are available for different sizes of punching machines and operational requirements.Special standard is also accepted.

1.Coil Car

The material is safely and smoothly moved to the main shaft expansion and contraction structure of the uncoiler to support the material during uncoiling so as to facilitate the material belt to smoothly enter the leveler, and the coil car is equipped with a material roll dumping prevention mechanism for moving narrower material rolls.

2.Decoiler Mandrel

A platform for fixing the inner diameter of the coil to the expansion and contraction portion and, as required, the material to be gap-rotated.

During the operation, the material is compacted to prevent the material roll from scattering. During the automatic operation, the material pressing wheel will automatically adjust the speed along with the change of the outer diameter of the material, so that the linear velocity of the material pressing wheel and the material roll is completely matched to prevent the material roll from scattering.

It is used to guide the material head to enter the leveling machine so that the material can smoothly enter the leveling mechanism.

5.Control Board

The main electric appliances are Japanese - imported An Chuan servo motors and Mitsubishi control systems, as well as imported touch screens, PLC and frequency converters. The control buttons of the operation panel are made of famous products such as Fuji of Japan.

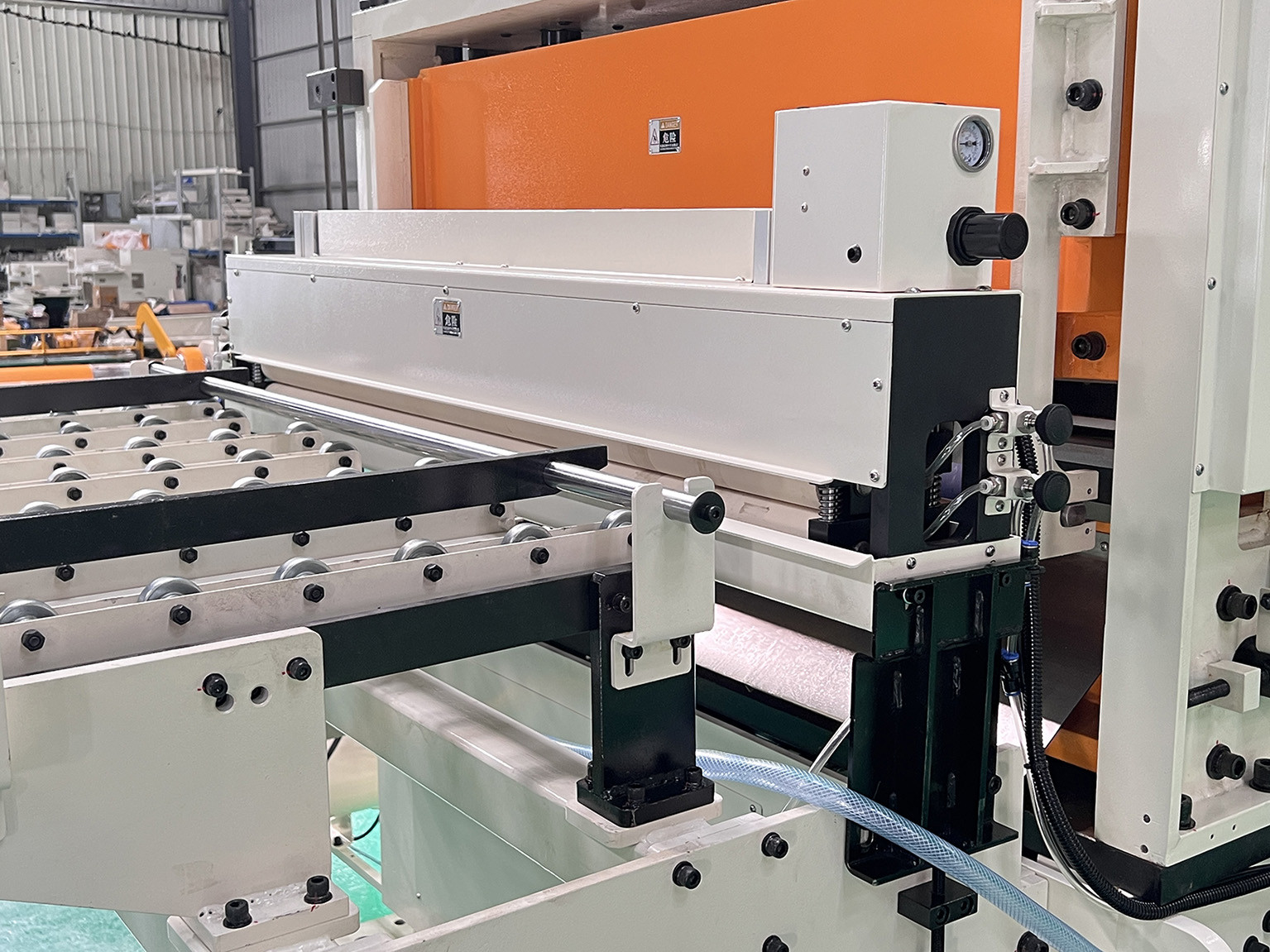

6.Hydraulic scissors

Plate shears are mainly used for cutting head and tail

materials.

Scissors are made of SKD12 and can be replaced on 4

sides.

7. Hydraulic Station

8.Outlet Support Bracket

It is used for smooth transfer between fixed-length feeding and die, and high-quality imported wear-resistant freighter is installed on the material support frame.

9. Optional Lubrication Unit

It is used for oiling the surface of the material, and the amount of oiling and oiling interval are electronically controlled and adjustable.

SPECIFICATION PARAMETER

|

Model

|

GLK04-600H

|

GLK04-800H

|

GLK04-1000H

|

GLK04-1300H |

|

Width of Material(mm) |

70-600

|

70-800

|

100-1000

|

100-1300 |

|

Max Coil Weight(kg) |

5000 |

5000/7000

|

7000

|

7000 |

Thickness of Material(mm) | 0.6-6.0 | |||

Coil I.D(mm) | Φ508 | |||

Max Coil O.D.(mm) | Φ1400 | |||

Max Feeding Length(mm) | ~500※ | |||

Max.line Speed(m/min) | 16-24 | |||

Working Rollers | 5 on top/4 on bottom | |||

Feeding Rollers | 1 group | 1 group | 1 group | 1 group |

Main Motor(kw) | AC7.5 | AC11 | AC11 | AC15 |

Uncoil Expansion | Hydraulic | Hydraulic | Hydraulic | Hydraulic |

Rack motor (kw) | 2.2 | 3.7 | 3.7 | 7.5 |

Power voltage(v) | AC220V 50HZ/AC380V 50HZ | |||

Operating Air (Mpa) | 0.5-0.6 | |||

|

Model

|

GLK04-600H

|

GLK04-800H

|

GLK04-1000H | GLK04-1300H | |

|

Thickness (mm) |

0.6~2.3

|

600 |

800 |

1000 | 1300 |

|

2.5

|

1000 | 1220 | |||

|

2.8

|

980 | 1150 | |||

3.2 | 714 | 924 | 1020 | ||

4.0 | 457 | 457 | 796 | 860 | |

4.5 | 361 | 361 | 667 | 780 | |

5.0 | 293 | 293 | 526 | 624 | |

6.0 | 203 | 203 | 423 | 469 | |

The above figures are the material having yield strength of 245N/mm² max

CORRECTION ABILITY

|

Model

|

GLK04-600H

|

GLK04-800H

|

GLK04-1000H

|

GLK04-1300H | |

|

Thickness(mm) |

2.3 |

556

|

753

|

824

|

1182 |

2.8 |

490

|

662

|

691

|

824 | |

3.2 |

295

|

556

|

593

|

635 | |

4.0 | 287 | 470 | 484 | 406 | |

4.5 | 257 | 338 | 352 | 321 | |

5.0 | 225 | 235 | 256 | 260 | |

6.0 | 165 | 168 | 173 | 180 | |

Application